Introduction to High-Performance Dispersants

In the demanding industrial environments of China, engines and heavy machinery are continuously subjected to extreme stress. High ambient temperatures in some regions, varying climatic conditions, and heavy operational loads make lubricant performance a critical factor for reliability and efficiency. In such environments, the importance of high-performance dispersants cannot be overstated. They form the backbone of modern lubricant formulations, ensuring that oils remain clean, effective, and protective even under the harshest operating conditions.

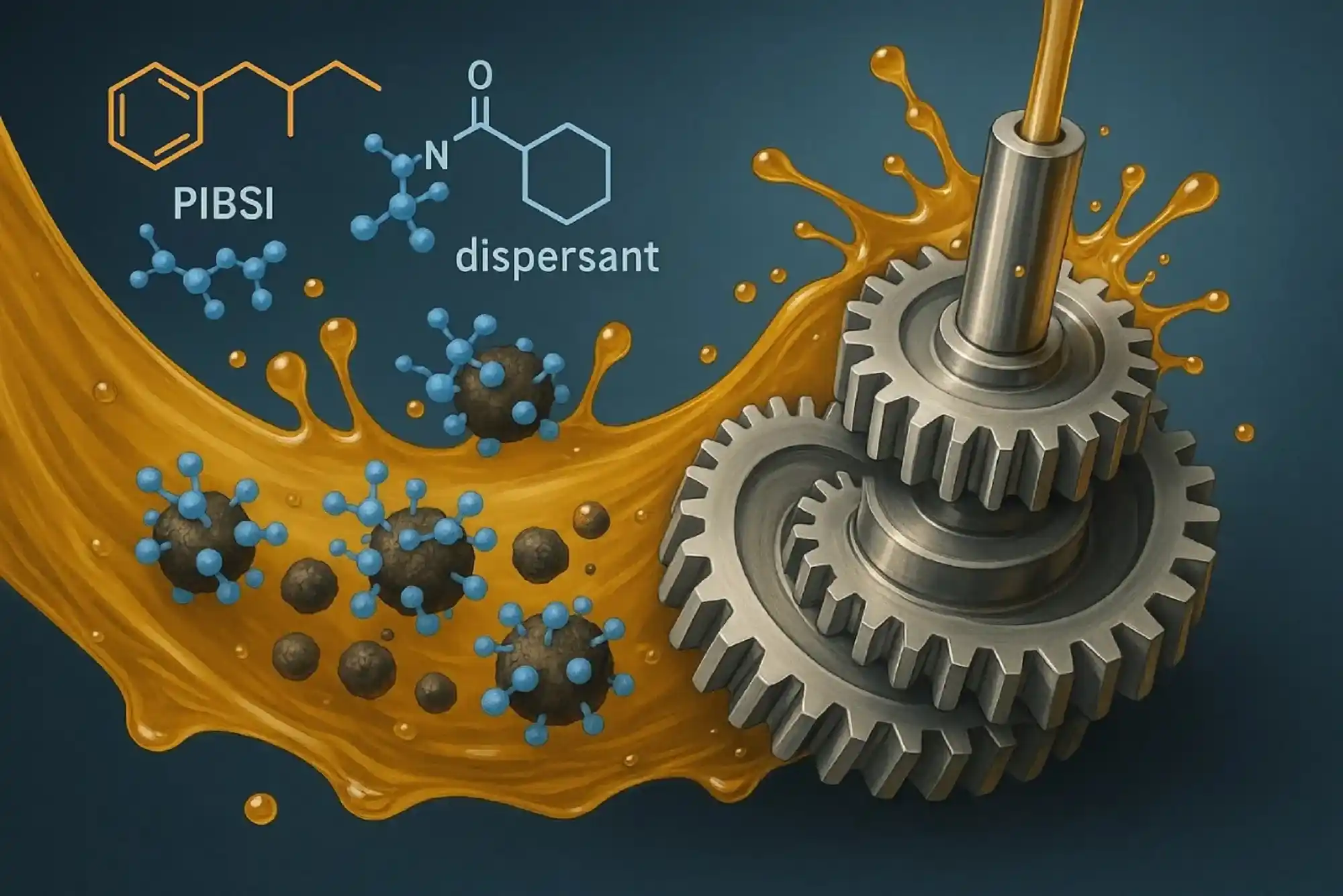

At their core, dispersants are chemical additives designed to keep insoluble contaminants evenly suspended in lubricants. Without dispersants, soot, sludge, varnish, and oxidation by-products would accumulate on metal surfaces, leading to deposits that degrade performance and shorten engine life. By dispersing these harmful particles, lubricants maintain their protective qualities, enabling engines and equipment to run smoothly for longer intervals.

For industries across China—ranging from transportation and construction to power generation, shipping, and manufacturing—understanding and selecting the right dispersants is not just a technical decision, but a strategic one. The choice impacts operational costs, environmental compliance, and long-term asset performance.

What is PIBSI Dispersant?

Polyisobutylene Succinimide (PIBSI) is one of the most widely used ashless dispersant additives in modern lubricants. Its reputation stems from its exceptional ability to combat the most common challenges faced by lubricants: sludge, varnish, soot, and oxidation by-products. In high-temperature environments found across China’s diverse industrial landscape, the PIBSI dispersant becomes indispensable.

Polyisobutylene succinimide is synthesized by reacting polyisobutylene with succinic anhydride, followed by further chemical modification to form a succinimide structure. This unique molecular arrangement provides high solubility in oil and an ability to attach itself to contaminants, keeping them suspended instead of allowing them to settle on surfaces. The result is a cleaner, more efficient engine or machine.

Some of the key roles the PIBSI dispersant plays in lubricants include:

- Sludge Prevention: Keeps harmful deposits from forming inside engines, particularly under high-load or stop-and-go operating conditions.

- Thermal Resistance: Maintains dispersing power even under extreme heat, which is vital for Chinese industries.

- Extended Oil Life: By slowing down oxidation and deposit buildup, polyisobutylene succinimide extends lubricant service intervals, saving costs for fleet operators and industrial facilities.

- Engine Protection: Reduces abrasive deposits that can lead to premature wear, ensuring smoother operation and longer equipment life.

PIBSI has therefore become the standard dispersant of choice not only in passenger vehicles but also in heavy-duty trucks, power generation equipment, and marine engines that must withstand demanding Chinese operating environments.

Ashless Dispersant Additives

Dispersants can generally be classified into two categories: conventional (metal-containing) and ashless. Conventional dispersants often use metallic compounds such as calcium or magnesium. While effective at controlling deposits, they produce ash residues during combustion. These residues can lead to clogged exhaust systems, higher emissions, and fouling of catalytic converters.

Ashless dispersant additives, in contrast, are formulated without metallic elements. They achieve the same or superior performance while leaving no metallic ash behind. This characteristic makes them particularly suitable for modern engines and industries where emissions regulations are strict and equipment reliability is critical.

Advantages of ashless dispersant additives include:

- Cleaner Operation: No metallic ash means reduced risk of clogging exhaust after-treatment systems or forming abrasive deposits.

- Environmental Benefits: Ashless dispersants support compliance with stringent emission standards in China and globally.

- Better Compatibility: Easily blended with a wide variety of base oils and additive packages, ensuring flexibility in lubricant formulation.

- Longer Equipment Life: By minimizing deposits and wear, ashless dispersant additives directly contribute to longer-lasting engines and machinery.

- Improved Reliability: Particularly valuable in high-demand industries where downtime is costly.

For the Chinese market, ashless dispersant additives offer a dual advantage: they deliver superior performance under diverse operating conditions while supporting sustainability and regulatory compliance. This makes them an attractive solution for both industrial and automotive applications.

Applications in the Chinese Market

China’s industrial and automotive sectors represent some of the most challenging operating environments for lubricants. From hot summer conditions in the south to cold winters in the north, combined with dusty construction sites and heavy machinery loads, lubricants are pushed to their limits. Under such conditions, dispersants become indispensable across multiple industries:

Automotive Lubricants

From passenger vehicles to commercial fleets, dispersants play a critical role in keeping engines clean and reliable. In high temperatures, engine oils oxidize faster, leading to sludge formation. Dispersants such as the PIBSI dispersant counter this effect by suspending oxidation by-products, ensuring engines run smoothly even during long-distance transportation or stop-start urban driving. For fleet operators in China, using dispersant-rich lubricants directly translates into reduced downtime, fewer breakdowns, and lower operating costs.

Industrial Machinery

Industries across China—from construction and manufacturing to petrochemicals—rely on heavy machinery operating under continuous high-load conditions. Industrial lubricants fortified with ashless dispersant additives prevent varnish, sludge, and deposit formation, ensuring uninterrupted operation. This not only reduces maintenance downtime but also maximizes productivity in sectors where time is money.

Marine and Shipping Applications

China’s maritime industry, including shipping and offshore operations, faces its own set of extreme challenges. Marine engines run for extended hours under high stress and high temperatures. Without effective dispersants, these engines would quickly suffer from deposit buildup, corrosion, and premature wear. Ashless dispersant additives ensure engine cleanliness, reduced wear, and compliance with international maritime emission standards.

High-Temperature Operations

China’s diverse climate means equipment must perform under both extreme heat and cold. Dispersants such as polyisobutylene succinimide are engineered to resist thermal degradation, meaning they maintain performance at higher temperatures where conventional additives fail. This is critical not only for vehicle engines but also for power plants, mining equipment, and heavy-duty industrial machines that cannot afford unexpected downtime.

Why Polyisobutylene Succinimide (PIBSI) is Key

While there are multiple types of dispersants, the PIBSI dispersant remains dominant due to its robust performance across diverse conditions. Its molecular design makes it especially effective in preventing sludge and varnish while ensuring compatibility with modern lubricant technologies.

Some of the reasons polyisobutylene succinimide is considered indispensable include:

- Thermal Stability: Retains effectiveness even at extreme operating temperatures, ensuring consistent protection in Chinese climates.

- Deposit Control: Prevents soot, sludge, and oxidation products from adhering to critical engine parts.

- Fuel Economy Benefits: Cleaner engines operate more efficiently, consuming less fuel over time.

- Versatility: Equally effective in passenger cars, commercial trucks, industrial equipment, and marine engines.

- Extended Oil Life: Slows oxidative degradation, allowing longer oil drain intervals and reduced maintenance costs.

For companies operating in China, PIBSI-based ashless dispersant additives are not just additives; they are enablers of long-term operational success. They help organizations optimize performance, reduce costs, and comply with international standards.

Choosing the Right Additive Supplier in China

The effectiveness of dispersants in lubricants depends not only on the chemical itself but also on the reliability of the supplier. Choosing a supplier in China is a strategic decision that impacts performance, compliance, and business continuity.

Key factors businesses should consider include:

- Quality Assurance: Additives should meet international standards for performance and safety.

- Technical Expertise: A supplier with deep technical knowledge can guide clients in choosing the right dispersant formulation for their specific needs.

- Market Understanding: Suppliers familiar with China’s industrial and climatic requirements can provide tailored solutions.

- Reliability: Consistent supply and product availability are crucial for avoiding operational disruptions.

- Compliance: Products should align with global and regional emission and environmental standards.

CheMost has built a reputation in China and internationally as a trusted supplier of high-performance dispersants, including PIBSI dispersant and other ashless dispersant additives. With a focus on quality, technical support, and market expertise, CheMost provides businesses with the confidence that their lubricants will perform as expected, even under the harshest conditions.

Conclusion

In the high-demand operating environments of China, the importance of high-performance dispersants cannot be overstated. PIBSI-based ashless dispersant additives ensure cleaner engines, longer oil life, improved fuel efficiency, and compliance with stringent environmental standards. Their role extends across automotive, industrial, and marine sectors, where equipment reliability and cost efficiency are top priorities.

For businesses seeking to maximize operational performance, choosing the right dispersants—and the right supplier—is a critical strategic decision. With advanced formulations, proven expertise, and a strong presence in China, CheMost stands out as the partner of choice for industries that demand reliability and efficiency. By investing in premium dispersants today, organizations can safeguard their engines, reduce downtime, and secure long-term cost savings while meeting the challenges of tomorrow’s marketplace.

NOTE:

CompanyListing.ae – Business Listings & Guest Posting Services

At CompanyListing.ae, we help businesses strengthen their online presence through verified listings and high-quality guest posting opportunities. Our platform connects brands with a wider audience by providing trusted visibility, improved search rankings, and genuine authority building.

Whether you want to list your company for increased exposure or publish guest posts to gain valuable backlinks, CompanyListing.ae offers a professional, SEO-friendly solution designed to boost credibility and growth.

Partner with us today to showcase your business and expand your digital reach.