3D-Printing Firm Releases Materials Suite for Medical-Grade Parts

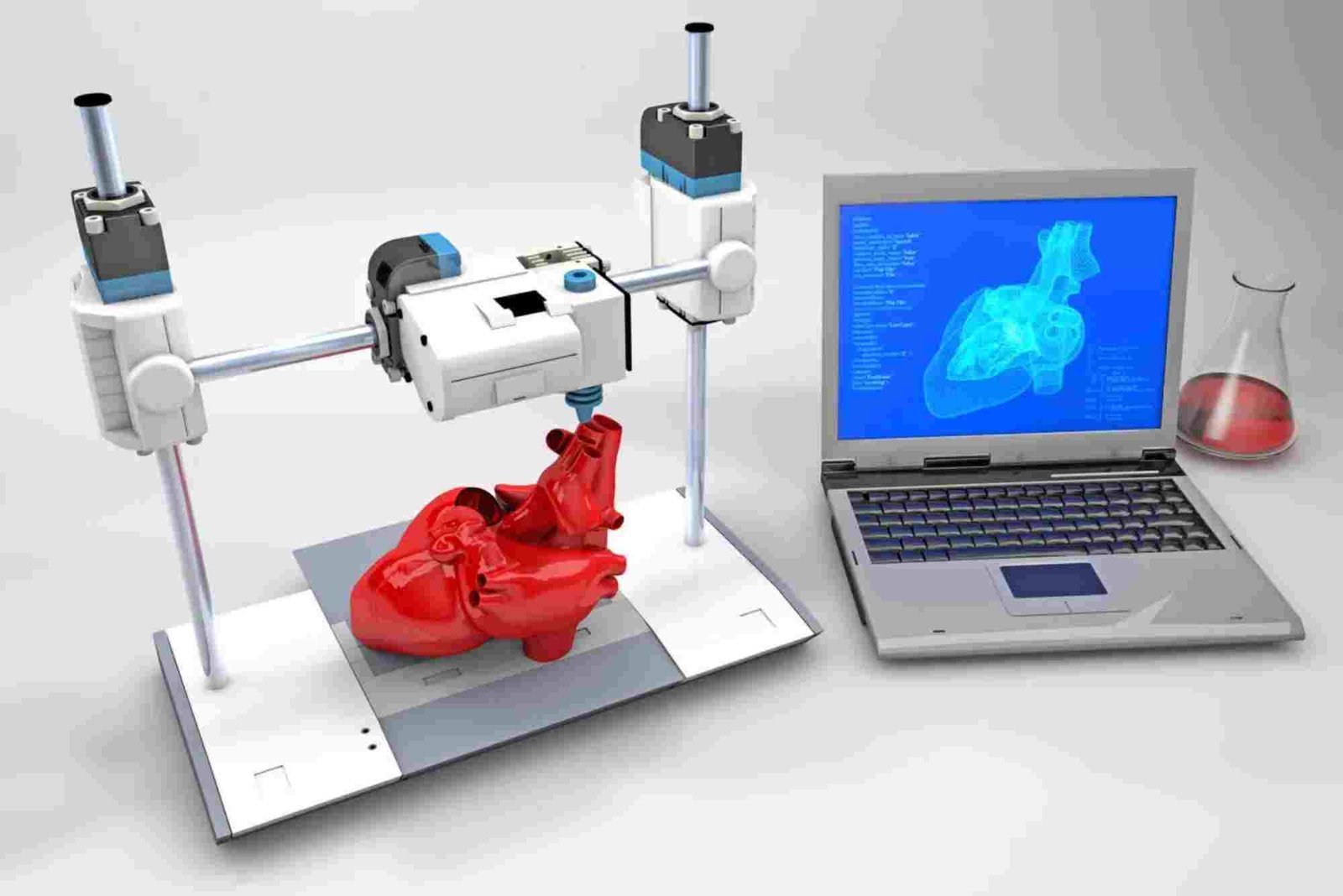

LEUVEN, Belgium – 1 December 2025 – Materialise NV today unveiled a comprehensive medical-grade materials suite that lets hospitals and device makers 3-D print end-use implants, instruments and anatomical models without the year-long qualification cycles that have slowed additive manufacturing in healthcare.

The “Mimics Care Materials” portfolio bundles six new laser-sintering and photopolymer resins—each pre-certified to ISO 10993 and ASTM F2026—with a cloud-based traceability platform that automatically generates FDA 510(k) submission packages. Early adopters at University Hospitals Leuven and Stryker Corp. have cut validation time 40 % compared with in-house development, according to data released by the company.

World-wide demand for patient-specific implants is rising 18 % annually, driven by ageing populations and the shift to outpatient surgery. Yet only 7 % of hospitals currently run point-of-care 3-D printing labs, citing material-biocompatibility paperwork as the top barrier, a 2024 survey by the U.S. Food & Drug Administration found. Materialise says its suite removes that hurdle by shipping resins with a digital “birth certificate” that logs powder lot, sterilisation window and mechanical-batch testing—documentation that typically adds six months to procurement cycles.

“We are replacing trial-and-error with turn-key compliance,” said Brigitte de Vet, vice-president of Materialise Medical. “A surgeon can order a PEEK cranial plate at 8 a.m., print it in a certified clean-room by noon, and implant it the same afternoon knowing every parameter meets FDA master-file standards.”

The flagship formulation is Mimics PEEK-MP, a high-temperature polymer reinforced with 5 % nano-hydroxyapatite that promotes osseointegration. In a 30-patient cranio-maxillofacial study led by Dr. Florian Thieringer at Basel University, implants printed with the material showed bone in-growth rates 22 % higher than standard PEEK after six months, results published in the Journal of Cranio-Maxillofacial Surgery this September.

Additional resins include PA-12 White, a sterilisable nylon for surgical guides; Titanium-ELI, a low-oxygen alloy validated for 3-D printed spinal cages; and TissueMatrix-Plus, a soft photopolymer whose Shore-00 30 hardness mimics myocardium for pre-operative rehearsal. All materials are manufactured under ISO 13485 quality systems at plants in Belgium and Michigan, then sealed in FDA-compliant clean-room packaging.

Materialise is pairing the launch with a subscription service that maps each resin to its Mimics inPrint segmentation software, allowing hospitals to move from CT scan to implant in under three hours. The company will charge USD 1,200 per litre for polymers and USD 950 per kilogram for titanium—pricing it says is on par with conventional machined stock once scrap and tooling costs are included.

Market tracker Wohlers Associates estimates the medical additive market will reach USD 9.5 billion by 2030, up from USD 2.4 billion last year. “Speed to surgery is the new competitive moat,” said principal author Terry Wohlers. “Vendors that bundle validated materials with regulatory data are positioned to capture the lion’s share of hospital capital budgets.”

Materialise plans to add bio-absorbable polymers for paediatric airway scaffolds in Q2 2026 and is negotiating pilot programmes with the U.S. Department of Veterans Affairs to supply point-of-care spinal implants at five VA hospitals.

About Materialise

Materialise NV, headquartered in Leuven, Belgium, has 35 years of experience in 3-D printing software and services. More than 200 hospitals worldwide use Materialise platforms for surgical planning, and the company’s manufacturing division has produced 1.8 million patient-specific devices to date.

Media Contact

Sarha Al-Mansoori

Director of Corporate Communications

G42

Email: media@g42.a

Phone: +971 2555 0100

Website: www.g42.ai