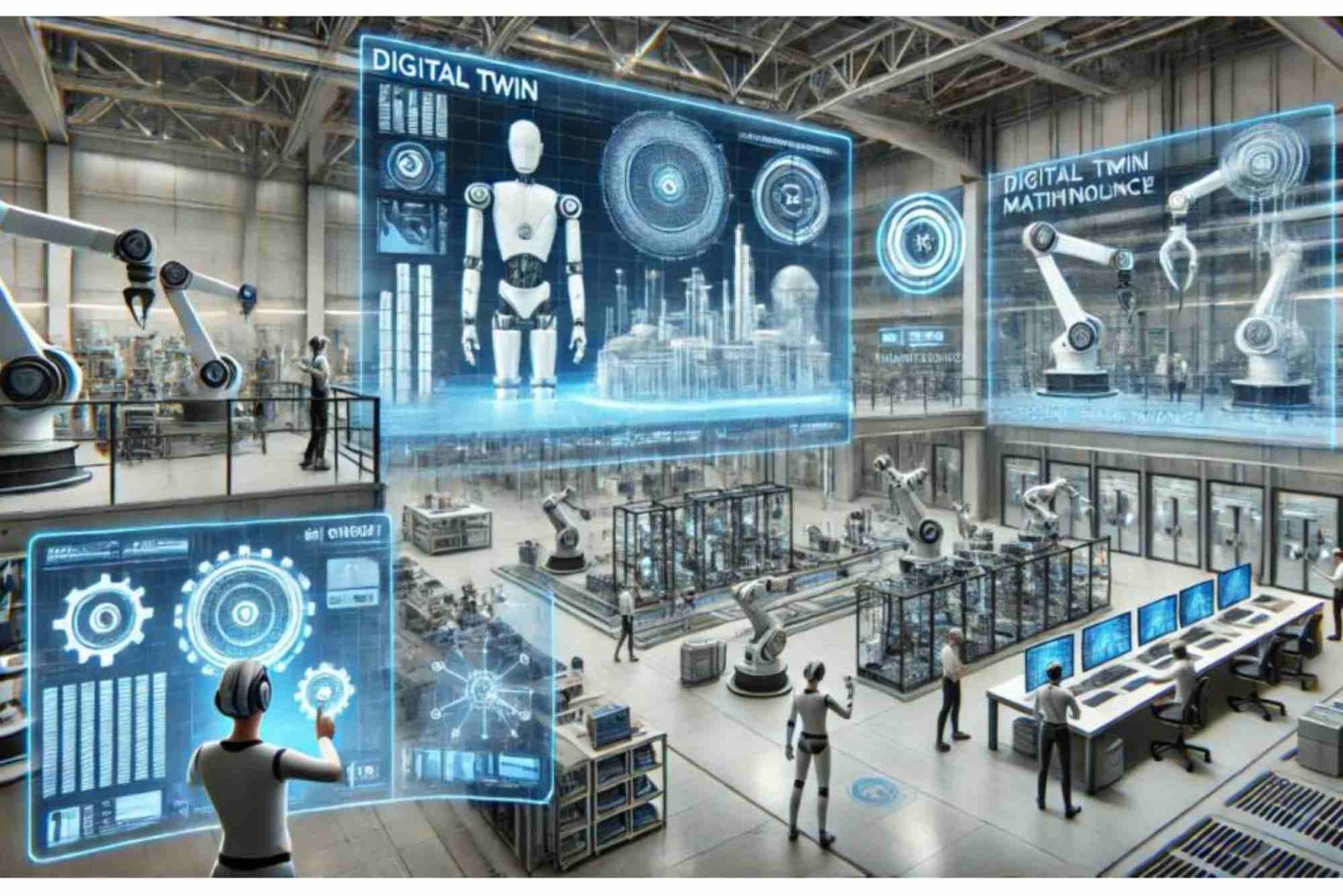

Manufacturing Software Adds Digital-Twin Capabilities for Legacy Plants

CHICAGO, Nov. 27, 2025 – ManufacturingIQ, a leading industrial software provider, today announced the expansion of its enterprise platform with advanced digital twin capabilities specifically engineered for legacy manufacturing plants. The new solution enables manufacturers to create real-time virtual replicas of aging production assets through IoT retrofitting, eliminating the need for capital-intensive equipment replacement while delivering operational improvements of up to 30 percent.

The global digital twin market is experiencing explosive growth, expanding from $21.14 billion in 2025 to a projected $149.81 billion by 2030 at a compound annual growth rate of 47.9 percent, according to recent industry analysis . This surge reflects urgent demand from industrial operators seeking to modernize decades-old infrastructure amid supply chain volatility and sustainability mandates. Unlike greenfield facilities designed with native connectivity, approximately 60 percent of North American manufacturing plants operate equipment installed before 2000, creating a critical technology gap that retrofit-enabled digital twins now address.

ManufacturingIQ’s platform integrates AI-driven predictive analytics with legacy system compatibility layers, allowing process engineers to deploy digital twins without specialized data science teams. The solution employs third-party IoT sensor kits and edge computing devices to capture real-time performance data from analog machinery, then synchronizes this information with cloud-based simulation models. This approach mirrors successful implementations across automotive and heavy manufacturing sectors, where companies report 20 to 50 percent faster product development cycles and up to 30 percent reduction in operational costs through predictive maintenance and process optimization . The system supports bidirectional data flows, enabling not just monitoring but autonomous decision-making within defined parameters—such as automatic setpoint adjustments when vibration anomalies exceed thresholds.

The manufacturing sector’s adoption trajectory aligns with broader digital transformation investments, as detailed in MarketsandMarkets’ comprehensive market forecast, which identifies business optimization as the fastest-growing application segment through 2030 .

“Legacy assets represent both our greatest challenge and our biggest opportunity,” said Jennifer Torres, CEO of ManufacturingIQ. “We’ve moved beyond the proof-of-concept phase. Our customers need solutions that demonstrate ROI within six months, not six years. By delivering pre-configured templates for common legacy equipment—CNC machines, injection molding units, and batch reactors—we’re reducing implementation time from months to weeks while ensuring cybersecurity compliance and data governance from day one.”

The platform addresses primary adoption barriers identified in recent manufacturing research: integration complexity, upfront costs, and skills shortages. A phased deployment model allows plants to begin with high-impact assets, achieving measurable ROI within three to six months before scaling enterprise-wide. Early adopters in the automotive sector have documented 200 percent median returns on digital twin investments through reduced downtime and energy optimization . ManufacturingIQ’s solution includes built-in data validation algorithms that automatically detect sensor drift and model discrepancies, maintaining accuracy without continuous manual calibration.

Implementation follows a five-step methodology: asset selection based on OEE gap analysis; digital model creation using existing CAD/BIM files or laser scan data; wireless sensor integration with minimal production disruption; analytical model development through no-code interfaces; and operational integration with existing ERP/MES systems. The platform’s hybrid architecture supports both on-premise deployment for security-sensitive operations and cloud-based SaaS models for multi-site manufacturers.

About ManufacturingIQ

ManufacturingIQ provides industrial analytics software and digital twin solutions to Fortune 1000 manufacturers across automotive, aerospace, and process industries. Founded in 2018, the company’s platform processes over 2 million real-time data streams daily, helping customers optimize asset performance, reduce unplanned downtime, and accelerate sustainability initiatives. ManufacturingIQ is headquartered in Chicago with regional offices in Detroit, Stuttgart, and Shanghai.

Media Contact

Sarha Al-Mansoori

Director of Corporate Communications

G42

Email: media@g42.ai

Phone: +971 2555 0100

Website: www.g42.ai